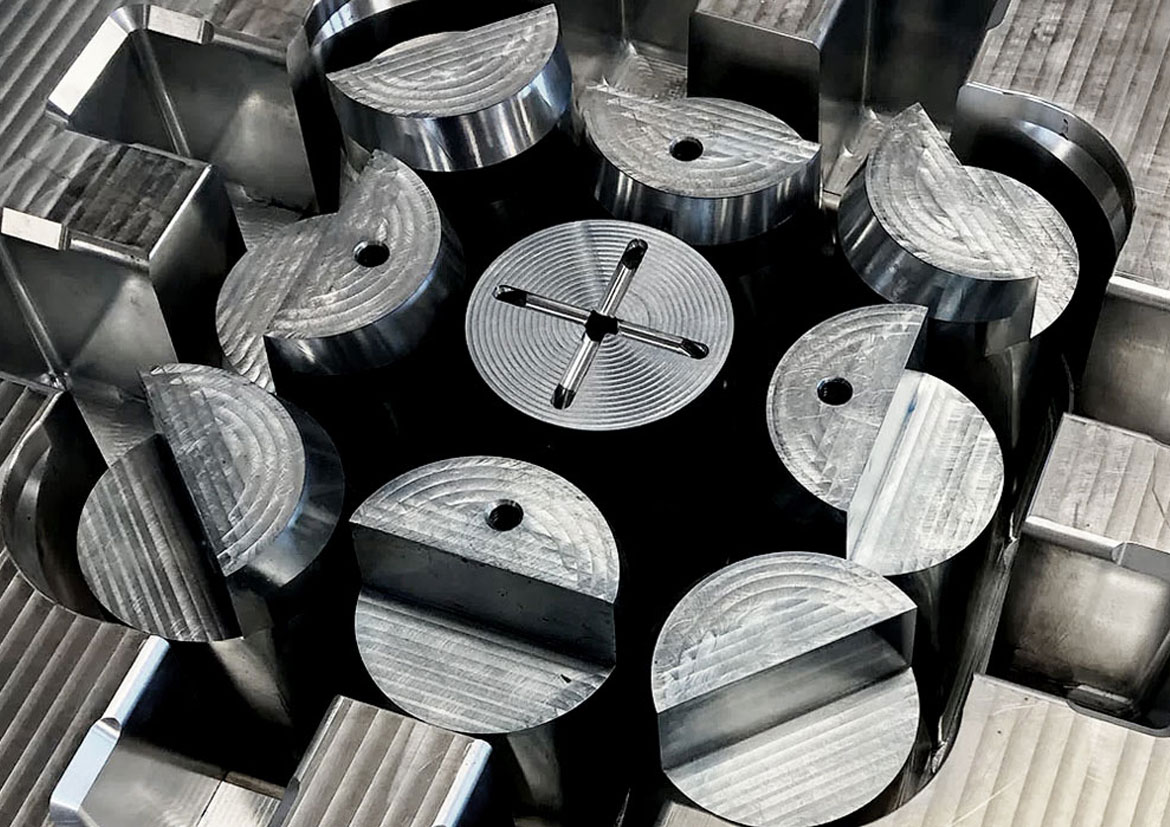

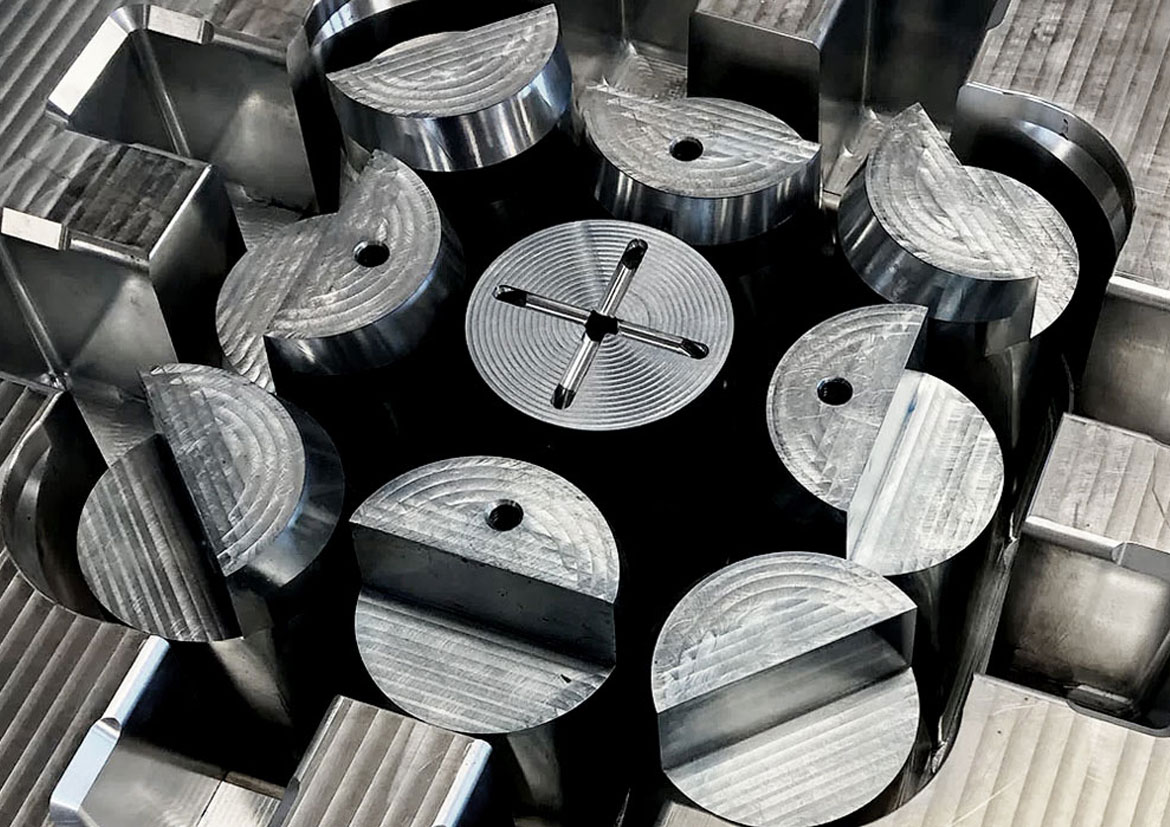

Mold Maintenance & Revision

ALYA offers mold maintenance and revision services to enhance production efficiency and extend mold lifespan. Regular maintenance keeps molds performing at their best, while revision work adapts molds to updated production needs.

Over time, molds used in production may wear out or require modifications to meet new technical requirements. At ALYA, we begin each project with a thorough inspection to determine the necessary maintenance or revision actions. These processes are carefully planned to restore the mold’s optimal performance.

Our services include wear removal, part replacement, surface renewal, and adjustments to dimensions and tolerances. Revision work may involve improving the mold’s existing design or functionality. At every stage, we adhere to strict quality standards, ensuring uninterrupted production operations.

Clients can easily submit their maintenance or revision requests via the quotation form on our website. Sharing project details helps us start the process quickly and plan accurately.

With a focus on quality, reliability, and on-time delivery, ALYA supports the smooth operation of your production lines through expert mold maintenance and revision services.